Tungsten Carbide Cobalt Sphere

Hard alloy balls with high hardness, wear resistance, corrosion resistance, bending resistance, commonly known as tungsten steel balls, refer to made of cemented carbide. Suitable for extremely harsh environments, extremely resistant to abrasion, impact, corrosion and deformation. The cemented carbide ball is based on a high hardness refractory metal carbide (WC, TiC) micron powder as main ingredient, with cobalt (Co) or nickel (Ni), molybdenum (Mo) as a binder,sintered into powder metallurgy products in a vacuum furnace or hydrogen reduction furnace.

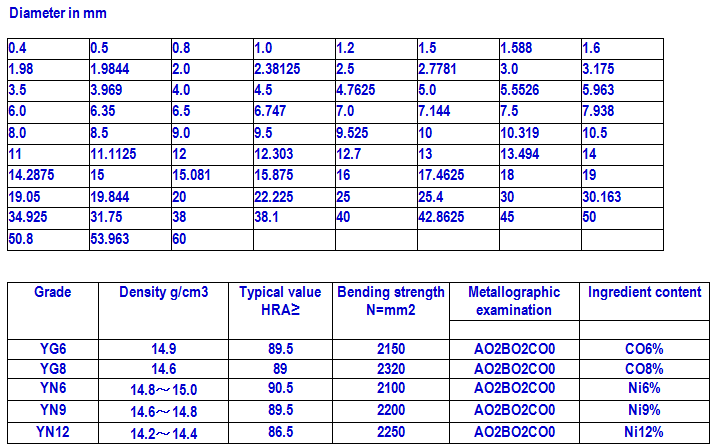

Common grades:

YG6, YG6x ,YG8 ,YG13,YG20 ,YN6 ,YN9 ,YN12 ,YT5,YT15

WhatsApp

WhatsApp QQ

QQ Email

Email Linked in

Linked in